Click on image to enlarge:

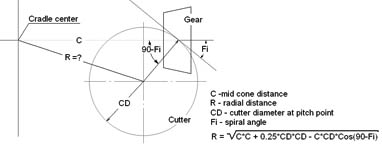

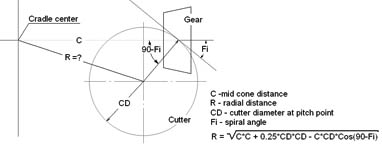

Radial distance is the distance from the center of the cradle (machine center) to the center of the gear cutting tool.

Changing the radial distance changes the spiral angle of the finished gear.

Cradle angle is the angular position of the cradle when the cutter is in the middle of the tooth space.

Setting a cradle angular rotation is not critical for the finished tooth geometry. Normally an experienced in

cutting operator would know at what angles to set the rotation of the cradle.

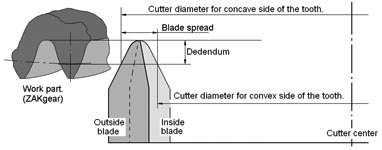

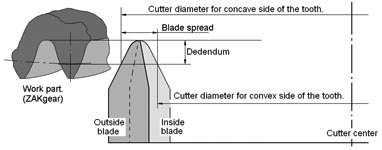

There is a practical reason for measuring ZAKGEAR cutters on the blade pitch points. Unlike the traditional spiral technology ZAKGEAR method allows calculation of the tooth geometry for the cutters with modified cutting edge including but not limited by Wildhaber-Novikov profile, root and tip relief, and tip and root radius. In general, the geometry of ZAKGEAR spiral bevel cutting blade is given by a list of x,y,z co-ordinates of the cutting edge points. While Direct Digital Simulation method determines the number of points [2n+1, n=1,2,3…], x,y,y co-ordinates can be, frankly, any realistic numbers.