Spiral Bevel Gear software.

By Dr. Stepan V. Lunin.

Download sample IGES file.

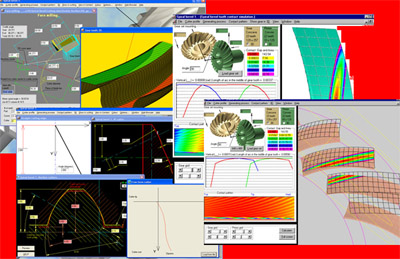

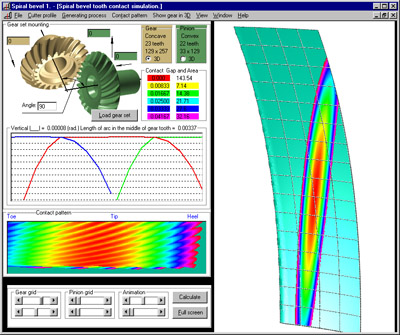

This software was the most advanced spiral bevel gear software of the 20-th century. Even today it is still the only spiral bevel software that

can simulate generation of a complex tooth form and a high resolution contact pattern. The mathematics of the software is based on the Direct Digital Simulation Method. that was incorporated with numerous mathematical tools for higher calculation performance.

that was incorporated with numerous mathematical tools for higher calculation performance.

The production of new advanced gears required more advanced calculation tool that traditional spiral bevel software could not offer.

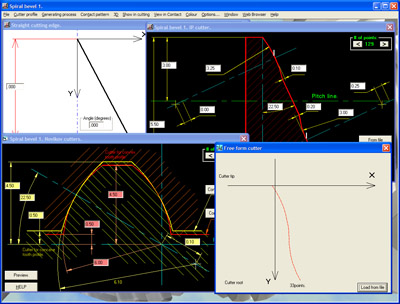

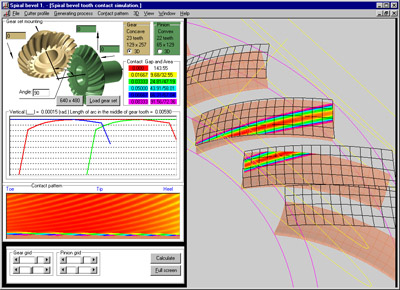

DDS based spiral bevel gear software is capable to simulate the geometry of any tooth form. The input options allow to select a common cutter geometry or input the cutter geometry from the file of x,y co-ordinates.

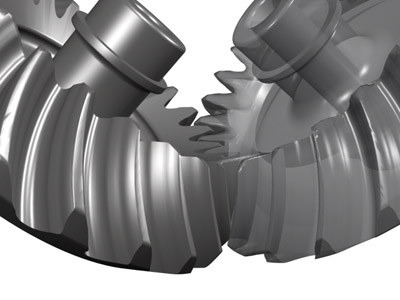

The generation process can be visualized in 3-dimentional window so you can see how the material is removed from the gear blank.

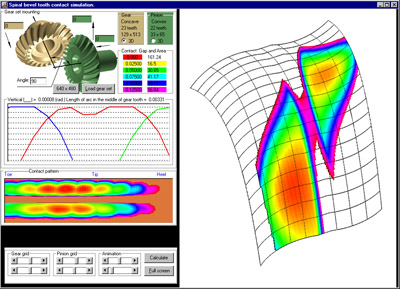

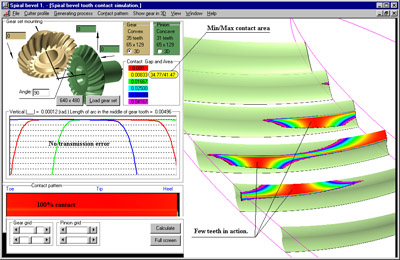

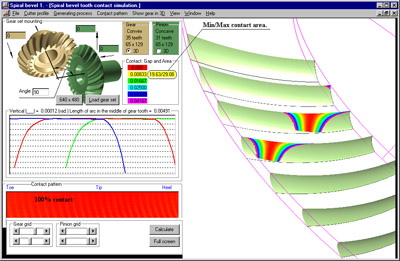

The software has an extended 3-dimentional-visualization module similar to common CAD programs. The final contact pattern can be visualized in 3-dimentional window.

The window can show instant and integrated contact pattern. It can also show animation of the contact pattern during the rotation of the gears.

You can easy misalign the gears and see how the contact pattern deviates from the nominal position.

The program also provides the transmission error for each tooth.

The program calculates the friction and load for each individual point on the tooth surface in order to provide accurate data for driving efficiency calculation.

The program was used for design and development of advanced not involute gears.

Home page:

www.zakgear.com