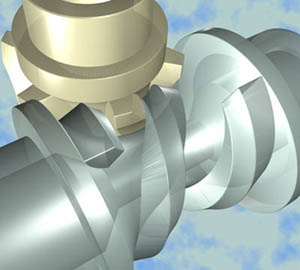

Globoid. Double enveloping worm gear.

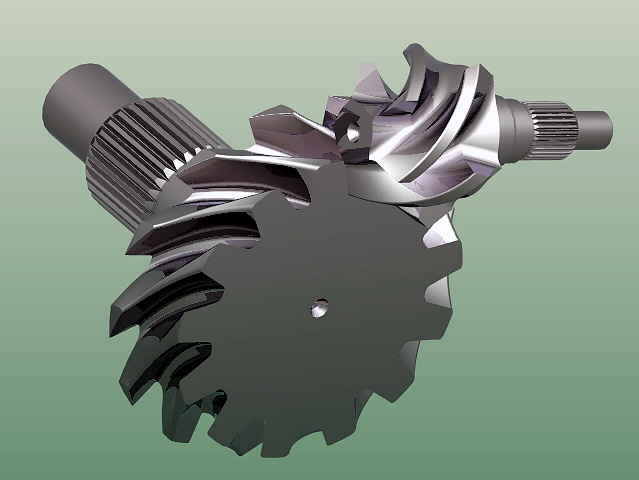

ULTRA GLOBOIDAL GEAR (UGG) ADVANTAGES

.

TRANSMIT MORE POWER WITH SMALLER GEARS.

Compact alternative for Hypoid and spiral bevel gears in low ratio applications.

UGG has high torque capacity due surface to surface contact mesh that reduces contact stresses.

In automotive power train applications like front and rear drive axles, power take-off units, traction systems and mechanical amplifiers it saves space up to 30 % and significantly reduces weight. It will work in power windows and power seats, steering drives.

EFFICIENCY IS EXTRIMALY HIGH.

Ii the traditional engineering practice globoidal (double enveloping) gears have been used with the ratio 1:5 and higher. hypoid and spiral bevel gears are always been used in the lower ratio applications. For the ratio less than 1:5 UGG can be more efficient than a right angle gear. UGG has higher percentage rolling/sliding motion and excellent dynamic lubrication. It has extending life even without lubrication. UGG can replace any right angle gears, especially in power sensitive applications, like helicopters, ships, boats and cars.

LOWER NOISE

Each thread of the pinion most of the time is in mesh with two teeth. It reduces impact of engagement and disengagement, increases the contact ratio and makes quieter motion.

MANUFACTURABILITY.

Using existing gear cutting machines can make UGG chipper than hypoid or spiral bevel gears. For some configuration forging technology or power metallurgy could be applied as well. There are very broad opportunities for the UGG made from plastic.

US patent # 6148683 in *.pdf format.

TRANSMIT MORE POWER WITH SMALLER GEARS.

Compact alternative for hypoid gears and spiral bevel gears in low ratio applications.

Download 3D animation. (1.65Mb)

Higher efficiency. Lower minimum ratio. Quiter motion. Ultra high torque capacity. US patent # 6148683.

This new globoid gear has surface to surface contact mesh and can replace low ratio right angle bevel and hypod gears in many applications.

Regular globoid worm.

Home page.